1436

Views & Citations436

Likes & Shares

Background: Candesartan Cilexetil is widely

prescribed antihypertensive. The drug is unfortunately available in the market

only as tablets which are not suitable for children and patients on nasogastric

feeding.

Objectives: The study aimed to formulate and

evaluate an appropriate extemporaneous oral suspension of candesartan

Cilexetil.

Methods: Six oral suspension formulations

of the drug were prepared from the 16 mg tablets of the innovation brand

(Atacand®) of the drug. All formulations were prepared as “flocculated

suspensions with a structured vehicle as a final product” with differences in

the speed of mixing applied.

Results: Formulations with high-speed

mixing were more viscous and more difficult to be poured than those prepared

using low-speed mixing. Of the later, one formulation with increased amounts of

flocculating agent, viscosity enhancer and wetting agents showed proper

physical stability, flocculation and a shelf-life of more than 1 year.

Conclusion: A stable oral suspension of

candesartan Cilexetil extemporaneously prepared from the drug tablets which can

be easily prepared by pharmacists using available constituents, is invented in

this study.

Keywords: Candesartan, Extemporaneous, Oral

suspension, Formulation, Evaluation

INTRODUCTION

Pharmacists

are the health professionals who are trained to perform extemporaneous

compounding and it is a required competency of practice for registered

pharmacists in many countries [1].

Extemporaneous

compounding is the preparation of a therapeutic product for an individual

patient in response to an identified need. It is a practical way to have medicines

supplied when there is no other option. For example, compounding may be useful

for patients with dysphagia who are unable to swallow solid medications whole,

when an appropriate dose or dosage form is not commercially available, when

patients require an individualized dose, or when medicines must be delivered

via nasogastric or gastrostomy tubes.

It should

take place in community and hospital pharmacies. There are usually specialist

compounding pharmacies in major towns and cities, but any pharmacy may

undertake compounding as long as they have appropriate facilities according to

country-based legislation [2].

For

compounding, the active ingredient may be derived from commercially available

medications or the pure chemical. Sometimes compounding is as simple as mixing

a crushed tablet or the contents of a capsule in water to form a solution or

suspension. However, this may not be suitable and depends on the solubility of

the active ingredient. For example, insoluble tablet excipients can lead to blockages

in enteral feeding tubes. In the majority of compounded products, additional

non-active components (excipients) are

included to ensure the active ingredient

dissolves or remains suspended, or to adjust palatability or viscosity [3].

Risks in

off-label compounding include using incorrect

formulae and calculations, selecting

incorrect ingredients, using incorrect quantities and producing unstable

products [1]. In community compounding, if a preparation error occurs, it would

only affect a limited number of patients. . Conversely, when pharmacy compounding

is done at a large scale e.g. in

hospitals

the error could potentially affect a large population of patients [4].

Candesartan

Cilexetil [1H-Benzimidazole-7-carboxylic acid, 2-ethoxy-1-[[2¢-(1H-tetrazol-5-yl)

[1, 1¢-biphenyl]-4-yl] methyl]-, 1[[cyclohexyloxyy) carbonyl] oxy] ethyl ester

[5] is an oral drug belonging to the category angiotensin II receptor blockers

(ARBs). It is prescribed for hypertension (adults and children) and also for

congestive heart failure (adults). The dose for children (1-6 years) is 0.2

mg/kg a day or divided every 12 h, (6-17 years) 4-8 mg day. The drug is

available commercially as tablets (4, 8, 16 and 32 mg) [6,7]. The drug is

practically insoluble in water [8]. It has pka value of 6.0 and its partition

coefficient (Octanol/aqueous) at pH 1.1, 6.9 & 8.9 is >1000 indicating

high hydrophobicity character [9].

Physicians

in Yemen sometimes prescribe candesartan Cilexetil for patients who cannot

swallow the tablet form including children or patients on nasogastric feeding.

Unfortunately, the drug is only available only as tablets. Therefore, for those

patients, they recommend to crush the tablet and mix it with milk or juice and

give it to the patient peroral. This is absolutely a non-evidence-based

practice since no studies have revealed its validation. Hence, the need for

valid extemporaneous liquid preparation of the drug becomes mandatory.

METHODS

Materials

& instrumentation

Reference standard of candesartan Cilexetil

was a gift from Yemeni- Egyptian Pharma Co., Sana`a, Yemen. Atacand®

(Candesartan Cilexetil 16 mg tablets; Astra-Zeneca, Switzerland) was a gift

from In-patient pharmacy at Al-Thawra Public hospital. UV spectrophotometer

(Shimadzu, UV-1800, Japan), high speed Lab Disperser & mixer (AD500S-P,

Mxbaoheng, China).

Assay of Candesartan Cilexetil in Atacand® tablets

The assay

was conducted as described by Ravisankar P et al. [10]. A stock solution of the

standard reference of the drug was prepared in methanol (100 µg/ml). Serial

dilution of the stock solution was performed to yield 6 dilute standard

solutions of concentrations of 10-50 µg/ml. The absorbances of the solutions

were measured at 258 nm. The standard calibration curve was constructed and its

linearity equation was determined. Twenty tablets of Atacand® 16 mg

(theoretically contain 320 mg of Candesartan Cilexetil) were ground to powder

and sieved through mesh No. 60. A quantity of the sieved powder equivalent to

16 mg of the drug was taken and dissolved in methanol up to 100 ml. Dilution of

the resultant solution was made to provide a dilute solution with a theoretical

concentration (Ct) of 40 µg/ml whose UV absorbance was measured at 258 nm. The

test was conducted in a triplicate manner. The UV absorbance was introduced

into the calibration linearity equation to calculate practical concentration of

the drug (Cp). Drug content was then calculated as follows:

Drug content % = 100 x Cp / Ct

Formulation of oral

suspensions from Atacand® tablets

Six suspension formulations (Table 1) were prepared using the

method of “flocculated suspension with structural vehicle” [11]. Atacand® 16 mg

tablets were used as source of active ingredients. Twenty tablets were ground

to powder and sieved through mesh No. 60. The powder was then levigated with

glycerin and polysorbate 20. Sodium chloride (flocculating agent) was dissolved

in few amount of water and then was added to the levigated mass and triturated.

Then, the structured vehicle was prepared as a solution of methylcellulose in

an amount of water representing two-third of the final suspension volume. All

other ingredients was dissolved in the structured vehicle. The resultant

solution was added into the flocculating-added levigated mass with thoroughly

stirring by the mixer for 15 min. The produced suspension was transferred to a

volumetric cylinder and the volume was completed to the desired volume with water.

Evaluation of oral suspension formulation

Drug content

To 1 ml of the suspension (theoretically

contained 16 mg candesartan Cilexetil), 7 ml of water was added and the mixture

was centrifuged at 2000 rpm for 12 min. The supernatant was discarded and 10 ml

of methanol was added to the residue and the resultant was then filtered. The

volume of filtrate was completed to 16 ml with methanol. 1 ml of this solution

was then diluted to 40 ml with methanol producing a theoretical concentration

(Ct) of 40 µg/ml. The UV absorbance at 258 nm of the solution was measured. The

test was carried out in triplicate pattern. The drug content was then

determined as described earlier in assay of the drug in Atacand tablet [10].

Physicochemical evaluation

The particle size, sedimentation rate, pH,

sedimentation volume, degree of flocculation and viscosity of the formulations

were measured.

Particle size and sedimentation rate

They were measured as described in

literature [11, 12] by sedimentation method by standing for 24 h using Stock`s

Equation as follows:

d = 104. [(S.18.Y) /

((Ps –Po).g)] 1/2

where (d) was the particle size as

diameter of dispersed particles (µm), (S) was sedimentation rate (cm/s), (Y)

was viscosity of the formulation (dyne.cm-2s), (Ps) was

the density of dispersed particles (g.cm-3), (Po) was the

density of formulation vehicle (g.cm-3) and (g) was the acceleration

due to gravity (980.7 cm.s-2).

• Sedimentation

volume [11] was calculated after standing for 24 h as follows:

F = Vs/Vo

where (Vs) was the sediment volume after 24 h

standing and (Vo) was the original suspension volume.

• Degree of flocculation [11]

It was measured by comparing the

sedimentation volume in the flocculated formulation to that of its

corresponding (sodium chloride free) suspension as follows:

β = F∞ /F

where (F) was the sedimentation

volume of the flocculated suspension and the sedimentation volume of the

suspension when deflocculated (F∞). As (β) increases (> 1) the

volume of sediment in the flocculated system is greater than that in the

deflocculated state which confirms the flocculation of the system.

•Viscosity of the suspension [13]

It was measured using Ostwald tube using H2O

as reference standard (H2O) which has a viscosity of (0.01 dyne cm-2

s).

Viscosity of the suspension was calculated as

follows

Y s = ts

x Y w / tw

where (Y s) and (Y w) were viscosity in (dyne.cm-2s)

of the suspensions and water, respectively, and (ts) and (tw)

were flow times of the suspension and water, respectively.

Accelerated stability study [13]

The suspension formulation with appropriate

drug content and physicochemical properties was selected for stability study in

order to determine its shelf life.

A sample of 50 ml of this

formulation was incubated at three different conditions 37, 50 and 75°C for 6 weeks. At intervals of 2,

4 and 6 weeks, each formulation was tested for its drug content. The results of

drug content were used to predict the shelf-life using Arrhenius equation. The

order of degradation reaction was determined by fitting data of drug content

vs. time to zero, first and second-order models at each storage temperature.

The model that showed higher correlation coefficient was the order of

degradation to which data fitted at a given temperature and the rate constant

of degradation (k) of that order was then determined. Arrhenius plot was

constructed with ln k (at y axis) versus I/T (at x axis); where T was the

temperature of storage in Kelvin. The regression equation of the plot was then

determined where the slope and intercept was used to calculate the expected

degradation rate constant at 25°C (K25) as follows

ln K25 =ln A – [(Ea/R). (1/T25)

where (ln A) was the intercept;

(Ea/R) was the slope of the plot.

The expected shelf-life (t90)

was calculated as follows

t90 = (0.1 * Q0)/K25

where Q0 was then drug content %

at the beginning of the stability study.

RESULTS

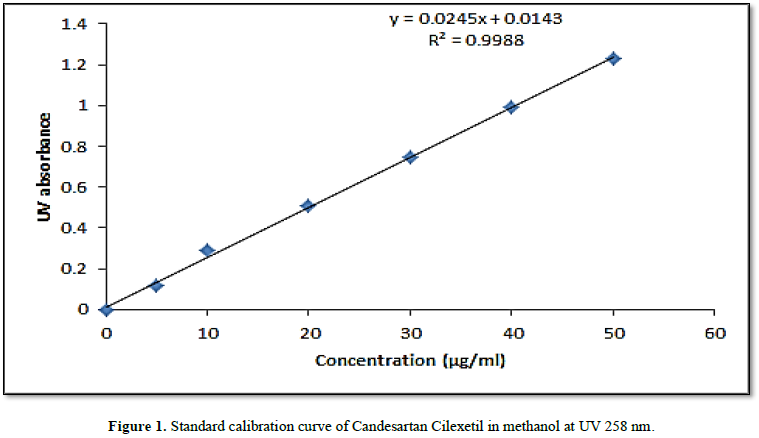

Standard calibration curve

A linear curve was obtained for

concentrations (10-50 µg/ml) of candesartan Cilexetil standard in methanol. The

linearity coefficient was 0.9988 and the curve equation was (y = 0.0245x +

0.0143).

Drug content in Atacand® 16 mg tablets

The average ± SD of drug content %

was 100.15 % ± 0.05 (CV was 0.05%; C.I. 95 % was (100.093 – 100.207 %).

Evaluation of suspension formulation

Drug content

The drug content of the drug in

all formulations, as shown in Table 2,

was within the range of 98.7–101% (95 % C.I. 92.422 -106.578 %). CV% (the

coefficient of variation) of all measurements, within each formulation, were

<5% indicating optimum precision.

Physicochemical properties

As shown in Table 1, there were two categories of formulations (Fa) with lower

mixer speed and (Fb) with higher mixer speed) and each category was divided

into 3 subcategories according to the amount of wetting agents, flocculating

agent and suspending agent where the formulation with the numbers 1, 2 and 3

denoting the smallest, intermediate and largest amounts of such

Table 3

demonstrates the results of physicochemical properties which showed significant

smaller particle size, higher degree of flocculation and lower sedimentation

rate of (Fb) formulations compared to (Fa) formulations. On the other hand,

there were no significant differences between (Fa) and (Fb) formulations

regarding sedimentation volume and pH. It was found that (Fb) formulations had

very large viscosity that made the suspension very difficult to be poured and

hence were excluded from further investigations.

Accelerated stability study

The formulation (Fa3) which showed proper

drug content, moderate viscosity, proper physical stability and flocculation

was introduced into an accelerated stability study. The order of degradation of

the drug at all the three storage temperatures fitted to first-order model.

Data obtained from Arrhenius plot was demonstrated in Table 4. The shelf-life of the drug in that formulation was 1.27

years.

DISCUSSION

Candesartan Cilexetil is yet available in the

market as commercial oral suspension. Instead, the innovator (Astra Zeneca)

recommends a method to prepare oral suspension from the available tablets [8].

The method requires the use of a specific vehicle products e.g. Ora plus (Perrigo,

Australia) which are unavailable in the Yemeni drug market.

The vehicle is composed of many

ingredients including: microcrystalline cellulose, carboxy methylcellulose,

xanthan gum, carrageenan, calcium sulphate, trisodium phosphate, citric acid,

dimethicone antifoam emulsion, methyl paraben and potassium sorbate [14]. Most

of these ingredients are expensive and unavailable in Yemen.

Crushing of Candesartan Cilexetil tablet then

mixing it with fluid has been recommended by some physicians in Yemen for

patients who cannot swallow tablets such as children. This practice may be

associated with great risks to patients’ due potential errors in formulation

and stability of the drug. Therefore, the present study aimed to offer another

option to physicians, patients by formulating a stable extemporaneous oral

liquid of the drug which can be simply prepared by pharmacist.

Therefore, this study was

undertaken in order to provide an oral suspension formulation with simple

formulation from available ingredients.

The

drug was formulated as an aqueous suspension owing to the numerous advantages

of this liquid dosage form including the non-necessity of dissolving the drug,

which is insoluble in water, the ability of suspension to mask unpleasant taste

of the drug and the enhanced chemical stability of drugs when formulated as a

dispersion system [13].

Prior to formulation, it was

necessary to confirm the drug content in the tablets. This was carried out

using the simple technique of UV spectrophotometry. A standard calibration

curve was constructed and revealed high linearity (Figure 1) and the drug content in tablets complied the USP

specifications (90-100%) [5].

The formulations were prepared

from the (Atacand® 16 mg tablets) which is a brand widely available in the

market. This is an advantageous point as pharmacists can prepare the drug as

oral suspension whenever required with no need to import the raw material of

the drug which is considered uneconomic due to limited request of the oral

suspension of the drug.

As shown in Table 1, six suspension formulations were designed based on

preformulation data of the drug and the required excipients. All formulations

were prepared as “flocculated suspension in structured vehicle as final

product”. This system is well known with improved physical stability of the

product as it prevents sediment cake formation (flocculated system), enhances

the viscosity and reduces sedimentation rate (structured vehicle) [11,13].

The differences among those formulations were

in the in the speed of mixer applied (low speed 1000 rpm or high speed 6000

rpm), the amount of flocculating agent (sodium chloride), viscosity enhancer

and structured vehicle (methylcellulose solution), wetting agents including the

surfactant (polysorbate 20) and glycerin. Other ingredients included were of

the same type and quantity in all formulations. They included sodium dihydrogen

phosphate and dibasic sodium phosphate as a buffer pH 6.8, sodium benzoate as

preservative, sodium sulphite as antioxidant, ethyl maltol as caramel flavor,

caramel E 150 as coloring agent and saccharin sodium as sweetener [11,13].

Evaluation of the prepared formulations

reveled optimum drug content in all formulations and the precision of

measurements was confirmed with low CV% (Table

2). With respect to physicochemical properties, as shown in Table 3, the formulations prepared at

high-speed mixing (Fb1, Fb2 & Fb3) though were of better physical stability

characters with lower particle sizes and sedimentation rates, they showed very

high viscosity most probably due to thixotropic phenomenon [11,13].

Accordingly, they were very difficult to be poured and as a result they were

excluded from further investigations. The physicochemical properties of (Fa)

formulations were within standard suspension specifications. The particles size

was in the range of 11.2-18.3 µm compared to standard coarse suspension of

10-50 µm [11], the formulations viscosity was accepted (1.01-3.1 dyne cm-2

s) as it was more than that of water (1.01-3.1 dyne cm-2 s) [11] and

the degree of flocculation was >1 within the range of (1.2-5.1) which

confirmed the appropriate flocculation of the particles in the prepared

suspensions [11].

Among the low-speed mixing formulations, Fa3

which contained an increased amount of flocculating agent, wetting agents and

viscosity enhancer showed more appropriate characters in terms of higher

viscosity, lower particle size, higher sedimentation volume, higher degree of

flocculation and lower sedimentation rate than the other two formulations (Fa1

and Fa2).

In the last step of evaluation,

the selected Fa3 formulation demonstrated considerably long shelf life of more

than 1 year (Table 4) compared to

only 100 days reported with the use of oral-plus as vehicle [7].

CONCLUSION

The suspension formulation of Candesartan

Cilexetil (Fa3) prepared in this study from the drug tablets using simple

method and available constituents is a stable oral suspension of the drug that

can be extemporaneously prepared by pharmacists whenever an oral liquid

preparation of the drug is required.

CONFLICT OF

INTERESTS

The authors declare that there is no conflict

of interests regarding the publication of this article.

AUTHOR CONTRIBUTION

The correspondent author conceived the idea

and developed the theory of the presented work. All authors participated in

conducting experiments, performing the calculations, discussing the results and

contributing in the last manuscript.

1.

Kairuz TE, Gargiulo D, Bunt C, Garg S

(2007) Quality, safety and efficacy in the ‘Off-Label’ use of Medicines. Curr

Drug Saf 2: 89-95.

2.

James FR (2017) Extemporaneously

compounded medicines. Aust Prescr 40: 5-8.Jain A (2006) Waste management in Asian countries. UN Environment.

3.

British Association for Parenteral and Enteral

Nutrition (BAPEN) and British Pharmaceutical Nutrition Group (2004) Administering

drugs via enteral feeding tubes: A practical guide 2019.

4.

Gudeman JJ, Jozwiakowski M, Chollet J,

Randell M (2013) Potential risks of pharmacy compounding. Drugs R D 13: 1-8.

5.

United States Pharmacopeia and National

Formulary (2010) Rockville, MD: United States Pharmacopeial Convention (USP

33-NF 28).

6.

Medscape (2019) Candesartan Rx.

Accessed on 15th December, 2019. Available online a: https://reference.medscape.com/drug/atacand-candesartan-342314.

7.

Atacand (2016) Product monograph. Accessed

on 25th December, 2019. Available online at:

https://www.astrazeneca.ca/content/dam/az-ca/downloads/productinformation/ATACAND%20-%20Product-Monograph_001.pdf

8.

Atacand (2016) Highlights of prescribing

information. Accessed on 16th December, 2019. Available online at

https://www.accessdata.fda.gov/drugsatfda_docs/label/2016/020838s039lbl.pdf

9.

Cagigal E, Gonzalez L, Alonso R.M, Jiménez

RM (2001) pKa determination of angiotensin II receptor antagonistic (ARA II) by

spectrofluorimetry. J Pharm Biomed Anal 26: 477-486.

10.

Ravisankar P, Vidya Sree V, Manjusha K, Naga

Mounika Y, Srinivasa Babu P (2016) Validated UV spectrophotometric method for

quantitative determination of Candesartan Cilexetil in bulk and pharmaceutical

dosage form. Der Pharmacia Lettre 8: 252-257.

11.

Felton L (2013) Remington essential of

pharmaceutics, Pharmaceutical Press. The Royal Pharmaceutical Society, UK, pp:

371-378.

12.

Shid R L, Dhole SN, Nilesh K, Shid SL

(2013) Formulation and evaluation of nanosuspension for drug delivery of Simvastatin.

Int J Pharm Sci 22: 98-106.

13.

Aulton ME (2012) Pharmaceutics: The

science of dosage form design. Churchill Livingstone, UK.

14.

Preggio Australia (2019) Ora-Plus.

Accessed on 7th March 2020. Available online at:

https://www.perrigo.com.au/product/ethical-care/ora-plus/

QUICK LINKS

- SUBMIT MANUSCRIPT

- RECOMMEND THE JOURNAL

-

SUBSCRIBE FOR ALERTS

RELATED JOURNALS

- Journal of Immunology Research and Therapy (ISSN:2472-727X)

- Journal of Renal Transplantation Science (ISSN:2640-0847)

- Ophthalmology Clinics and Research (ISSN:2638-115X)

- International Journal of Clinical Case Studies and Reports (ISSN:2641-5771)

- Journal of Alcoholism Clinical Research

- Journal of Spine Diseases

- International Journal of AIDS (ISSN: 2644-3023)